By Mark Brooks

Canada has committed to achieving net-zero carbon emissions by 2050. Yet a recent report from Canada’s Energy Regulator (CER) predicts that by 2050 Canada will still need millions of barrels a day in hydrocarbon-based fuel. As the burning of liquid and gas fuels is one of the main sources of carbon emissions, how will this paradox be possible?

Surprise — not only will hydrocarbon-based fuels, such as Jet-A, diesel and gasoline be net carbon-zero, this transition is key to winning the fight against global warming. Even more interesting is that the twin lynchpins of the global capitalist economy, aviation and the oil industry, are at the heart of pushing new net-zero fuel technology.

While much attention has been paid to the electrification of cars, trucks and trains with new technology, the aviation industry has focused on recycling carbon already in the atmosphere to create fuel. Innovative research and chemical engineering know-how promise new alternative fuels that will enable net-zero carbon emissions without any changes to engines, equipment or the supply chain. The result is a winning approach to the war on global warming across all forms of transportation.

ICAO’s Plan

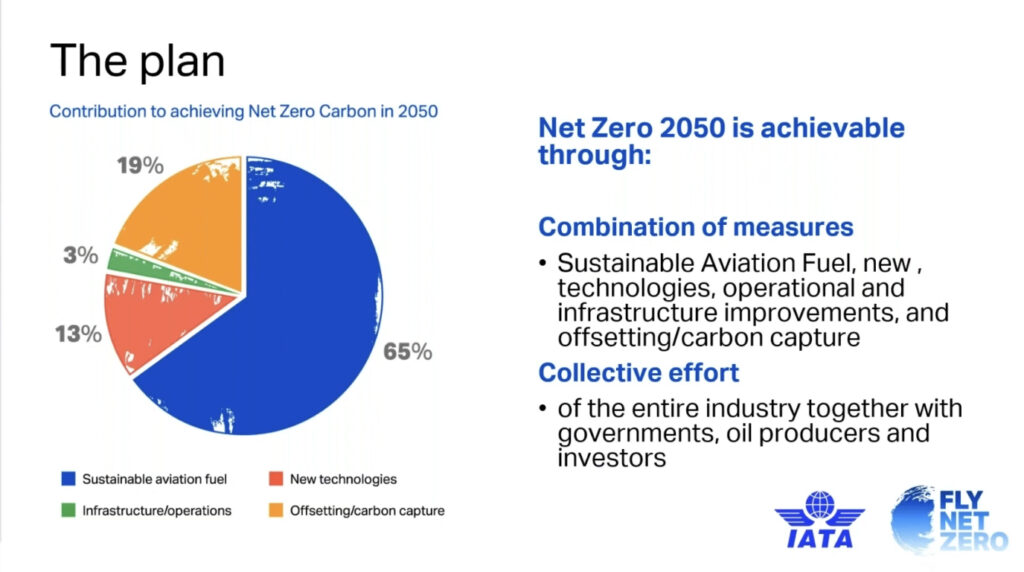

For more than a decade, ICAO (International Civil Aviation Organization, a United Nations agency based in Montreal) has been carefully planning out an answer to the question of how to achieve net-zero carbon emissions while enabling rapid growth across all sectors of aviation.

Their answer is a plan to net-zero emissions for the aviation industry worldwide endorsed by the IPCC (Intergovernmental Panel on Climate Change). It encompasses many elements including new more efficient engine and airframe technology, electric and hybrid electric flight, but relies on one core element, alternative fuel. The ICAO plan is focused on making the fuel aviation is using carbon-neutral (no net new carbon released into the atmosphere). Eight SAF (Sustainable Aviation Fuel) production methods have so far been endorsed, the most notable being synthetic fuel produced from renewable electricity and carbon captured right out of the air. IATA ( International Air Transport Association) just endorsed the plan committing its members to a net carbon zero future.

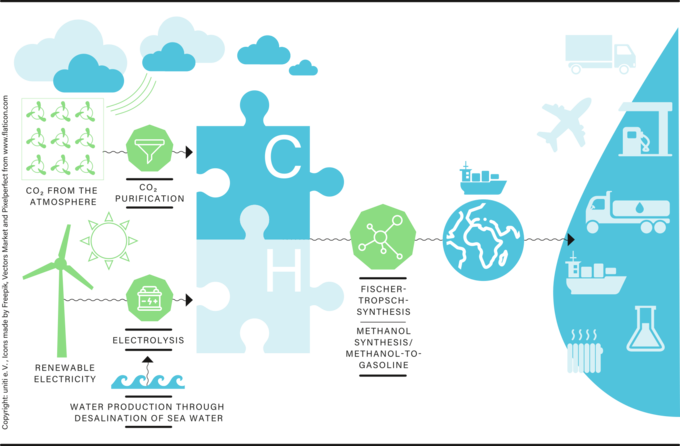

Sustainable PtL (Power to Liquids) or ElectroFuel (eFuel for short) is a family of synthetic fuels that can be created utilizing several well-known chemical reactions including the Fischer-Tropsch process. To put it simply, hydrogen is produced using renewable electricity from water and then combined with carbon dioxide, either from industrial exhaust gases or sequestered out of the air. The end product is a drop-in replacement hydrocarbon fuel of your choice with low or zero net-greenhouse gas emissions.

Unlike biofuels, eFuels do not compete with foodstuffs, nor require cutting down forests to feed a process, or require the logistics of moving large quantities of feedstock. Just as important, unlike biofuels, eFuel is not technically different than the conventional counterpart it is replacing. eFuel can be created to fill the tank of a classic car, an existing 18-wheeler truck, a ship, a Cessna 172, an Airbus 320 or a SpaceX Rocket. eFuels can fit into the existing network of filling stations, clean-product pipelines and tank storage systems for standalone delivery, or be blended seamlessly with existing fuels.

The technical term for this is “fungible” – eFuels are interchangeable with the fuel product they are replacing. You can mix them with the fossil fuel product, or biofuels, without performance consequences.

eFuel can reduce transportation-created carbon emissions to near zero while still utilizing the amazing flexibility and energy storage ability of liquid hydrocarbon fuels. The difference is that eFuel is just not produced from crude oil. 87% of diesel fuel or Jet-A is made of carbon. When a hydrocarbon molecule is burned, each carbon atom combines with two oxygen atoms to create carbon dioxide, a greenhouse gas that is released into the atmosphere. If renewable electricity is used to reverse this process, the carbon needed to create new fuel can be sourced right out of the air we breathe.

This solution can drop seamlessly into our existing supply chains without requiring changes to consumer behaviour, modifications to engines or the purchase of new vehicles. It can be scaled up to meet all our needs without digging up rare minerals or polluting the land. It can even make the air we breathe cleaner. If more carbon is captured from the atmosphere than is needed to produced fuel, it can be sequestered into other products including construction materials making fuel production and consumption net carbon negative.

eFuel is the creation of the global oil industry. It is a free enterprise-driven response to the global aviation industry’s demand for a cost-competitive net-zero carbon fuel. ICAO’s plan relies heavily on creating a marketplace for the new fuels by mandating its use. Once the volume of production reaches a critical size, the cost is expected to reach parity with traditional fuels and then those fuels can be phased out. This could potentially make existing in-ground oil reserves worthless in the near future.

The world’s airlines recently endorsed and committed to the ICAO plan, kick-starting a billion-dollar market for the new fuels. Thanks to the highly-regulated nature of international aviation, achieving net-zero emissions is now an achievable goal. Many international air carriers, such as Air Canada, have already announced a commitment to switch to these alternative fuels. Starting at 10% of alternate fuel consumption by 2030, this will move towards a goal of 100% by no later than 2050.

Aviation can be the first form of modern international transportation to achieve net-zero carbon emissions industry-wide.

Beyond its net-zero carbon footprint, eFuel solves other common logistical problems, including source security, fuel transportation and storage. eFuel can be produced locally on demand without the need to import feedstock from unstable overseas regions. eFuel’s production plants can be stand-alone operations or teamed with high-emissions industries such as a cement plant. While new clean-product pipeline connections may be needed, eFuels can be transported in the existing oil industry’s clean-product pipelines. Carbon dioxide can also be pulled from a number of other sources including multiple types of industrial emissions, non-recyclable waste plastic in addition to carbon sequestered right out of thin air.

Cost Parity, Investment and Canada’s Amazing Opportunity

Can the new fuel eventually be produced at parity to or even below today’s conventional fuel costs? While the claim by some of a cost as little as 30 cents per litre ($1 dollar per gallon) may seem like hype, it will depend on access to cheap, renewable electricity and the ability to produce the fuel at a large scale as close as possible to the point of consumption. Today, the cost of eFuels is several times that of fossile fuel.

A study in the science journal Nature gives a more realistic future estimate of $1.35 to $2 a litre. As production ramps up, costs per litre are expected come down. Cost can be further reduced if eFuel is created close the point of consumption or next to a heavy emissions source. Access to excess emissions-free electrical power is key. It is expected that scaling up alternative fuel production from all sources, including new eFuel production, will require tens of billions of dollars of new capital investments.

Canada’s existing oil industry already has experience in this scale of synthetic oil production thanks to the oil sands. It is also a world leader in carbon sequestering.

The Canadian Oil and Gas industry is working on sequestering CO2 from its operations and is now home to 20% of the world’s current or planned carbon sequestering projects. In the future, rather than pumping the CO2 back into the ground, it can use it as a feedstock for eFuel production. This will make carbon capture a profit-driven business.

For example, the province of Saskatchewan estimates that current and planned CCUS (Carbon Capture Utilization and Storage) projects in the province will sequester two million tons of CO2 a year. That is enough to create 600 million litres of fuel, 12 times the 48 million litres of 100LL aviation gasoline used by all of Canada’s general aviation fleet in 2018. The province sees the opportunity in Switching to eFuel technology to produce low- and net-zero carbon fuel. This could include 100UL (unleaded aviation gasoline) and Jet-A.

eFuel can provide a fast path to our net-zero carbon targets using our existing fleets of cars, trucks, trains and aircraft. In the long term, eFuel will be a permanent part of Canada’s green economy, powering critical parts of our transportation system that are hard to electrify, such as long distance trains, planes and trucks. Switching to eFuel production is faster, cheaper and more technically feasible than replacing existing fleets of trucks, locomotives and aircraft with battery/electric technology.

The Future Market for eFuels

Government pronouncements of banning internal combustion powered vehicles and mandating electric vehicle sales by 2030 might sound good during an election and play well in the media, but will not instantly convert existing cars to run on renewable energy. Mandating a switch to eFuel will. In comparison, electric vehicle incentive programs are financially inefficient approaches to reducing transportation emissions ($$/GHG tonne).

Canada’s Energy Regulator (CER) predicts that, even with aggressive incentives and mandates, by 2050 the Canadian economy will still need to produce 4.8 million barrels of oil a day, down from 5.8 million today. The production can be carbon neutral if alternative and eFuel production is encouraged.

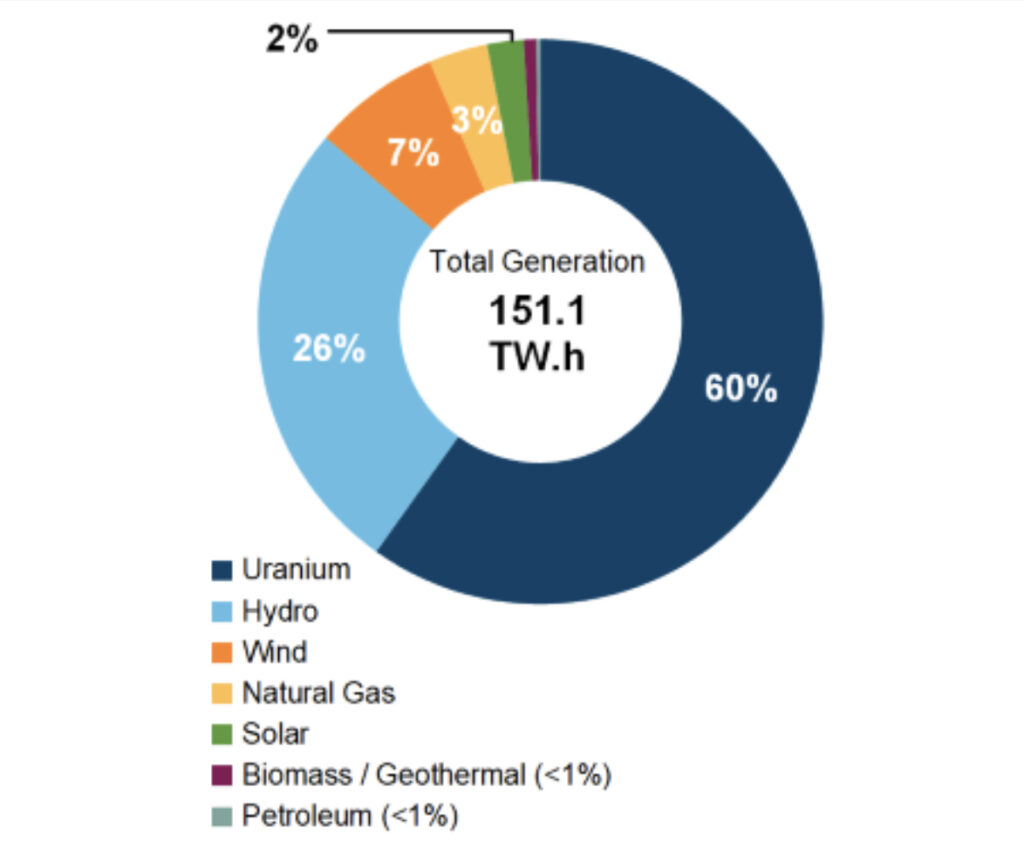

Canada is in a perfect spot to become a world leader in the production of eFuel thanks to the vast majority of our existing electrical energy production already coming from non-carbon emitting sources.

In 2020, Ontario exported 20 TWh of electricity. Just a fraction of a TWh (30 gigawatts) is enough to produce the 13 billion litres of jet fuel expected to be needed in Canada in 2050. That’s 50% more than the 8.8 billion litres of jet fuel consumed by all Canadian airlines in 2019. Aviation is planning to do this with a well regulated free market, why not the rest of our transportation sectors? With appropriate incentives and planning, our excess grid energy could be turned into enough eFuel to meet all our transportation demands and create a product for export.

eFuel is Green Energy Independence

Canada’s oil industry has been creating synthetic fuel from the oil sands for decades, and is familiar with the massive capital investments required to scale eFuel production. But unlike the oil sands, with this method, the carbon can be pulled right out of the air in a clear process that can be built close to the source of demand — our cities, logistics hubs and airports.

eFuel can be produced with excess zero emissions electrical energy in Ontario, Quebec and Newfoundland, removing the need to import crude oil into eastern Canada. Gone will be the need for importing oil from foreign nations with questionable emissions or human rights practices. Gone too will be the need for thousands of kilometres of crude oil pipelines traversing the prairie provinces.

New transportation infrastructure, such as the new airport being planned just east of Toronto in Pickering, can also be home to the new clean eFuel industry. On-demand production of eFuel in a clean process, close to the point of sale at an airport, will reduce the need for pipelines and large storage systems.

A new Canadian plant is now the first to produce e-Fuels in North American. With the support of the province of Quebec and the federal government, the SAF+ Consortium (“SAF +”) is planning large-scale production of sustainable eFuel for jets, at a facility located just east of Montreal, in 2025. Providing a sustainable solution for low-carbon flying (safplusconsortium.com)

As with all new technology, there will be detractors and naysayers, not the least reason being that all existing “oil reserves” will become worthless. The struggle to get to net carbon-zero just became a lot easier, thanks to a drop-in replacement fuel showcasing Canadian technology and innovation. eFuel is emerging as one of the energy industry’s most important paths towards a net-zero carbon future.

Related:

Explaining Canadas Sustainable Aviation Fuel opportunity – Friends of Pickering Airport

Aviation’s Two Paths To A Net-Zero Carbon Future – Friends of Pickering Airport

Aviation 25% of carbon emissions by 2050 is a Myth – Friends of Pickering Airport

Canada’s Carbon Neutral Aviation Challenge – Friends of Pickering Airport

References:

Companies in race to develop sustainable jet fuel in face of climate crisis | CBC News

GREET the Dawn of a New Day in Sustainable Aviation Fuels | Department of Energy

Home – eFuel Alliance (efuel-alliance.eu)

What is eFuel? How Porsche’s Synthetic Fuel Could Save the Combustion Engine » AutoGuide.com News

Alternative Fuels – Canadian Fuels Association

GAMI Awarded Long-Awaited STC For Unleaded 100-Octane Avgas – AVweb

Fischer–Tropsch process – Wikipedia

Sustainable aviation fuel is the key to the future of flying | World Economic Forum (weforum.org)

Roof top solar mini refinery makes kerosene from sunlight and air – Engineering Matters (reby.media)

Drop-in Fuels from Sunlight and Air | Nature

IATA – Net-Zero Carbon Emissions by 2050

Air Canada Commits to Ambitious Net Zero Emissions Goal by 2050 (newswire.ca)

EDITORIAL: Canada’s oil and gas sector is resilient | Toronto Sun

CER – Canada’s Energy Future 2021 – Key Findings (cer-rec.gc.ca)

national-GHG-emissions-en (canada.ca)

Net-zero carbon emissions by 2050 | Airlines. (iata.org)